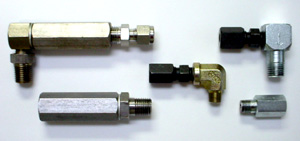

Premier Check Valves

Single Ball or Double Ball单球或双球止逆结构

Carbon Steel or Stainless Steel碳钢或不锈钢材料

Straight or Angle Type 直型和角型

Pressures to 8,000 PSI 压力可达8000PSI

?Part No. Max Psi Inlet Outlet Material

90023 8000 1/8” Npt 1/8” Npt Steel

90024 8000 1/4” Npt 1/4” Npt Steel

90254 8000 1/8” Npt 1/4” Npt Steel

90255 8000 1/4” Npt 1/8” Npt Steel

90025 8000 1/8” Npt 1/8” Npt Stainless

90026 8000 1/4” Npt 1/4” Npt Stainless

90291 8000 1/8” Npt 1/4” Npt Stainless

90290 8000 1/4” Npt 1/8” Npt Stainless

Part No. Max Psi Inlet Outlet Material

90104 8000 1/8” Npt 1/8” Npt Steel

90103 8000 1/4” Npt 1/4” Npt Steel

90112 8000 1/8” Npt 1/4” Npt Steel

90296 8000 1/4” Npt 1/8” Npt Steel

90105 8000 1/8” Npt 1/8” Npt Stainless

90106 8000 1/4” Npt 1/4” Npt Stainless

90297 8000 1/8” Npt 1/4” Npt Stainless

90108 8000 1/4” Npt 1/8” Npt Stainless

Part No. Max Psi Inlet Outlet Material

90033 8000 1/4” Tube 1/8” Npt Steel

90101 8000 1/4” Tube 1/4” Npt Steel

90034 8000 1/4” Tube 1/8” Npt Stainless

90109 8000 1/4” Tube 1/4” Npt Stainless

Part No. Max Psi Inlet Outlet Material

90107 8000 1/4” Tube 1/8” Npt Steel

90102 8000 1/4” Tube 1/4” Npt Steel

90110 8000 1/4” Tube 1/8” Npt Stainless

90111 8000 1/4” Tube 1/4” Npt Stainless

Part No. Max Psi Inlet Outlet Material

90501 3000 1/8” Npt 1/8” Npt Steel

Part No. Max Psi Inlet Outlet Material

90040 3000 1/4” Tube 1/8” Npt Steel

90329 3000 1/4” Tube 1/8” Npt Stainless

Part No. Max Psi Inlet Outlet Material

90043 3000 1/4” Tube

Flared

1/8” Npt Steel

Part No. Max Psi Inlet Outlet Material

90287 6000 1/4” Tube

Flared

1/8” Npt Steel

Part No. Max Psi Inlet Outlet Material

90336 3000 1/4” Npt 1/4” Npt Stainless

Part No. Max Psi Inlet Outlet Material

90731 3000 1/4” Tube 1/4” Npt Steel

Operation (Double Ball Check Valves)

Flow entering the check valve creates pressure on the smaller diameterball. If the pressure created is higher than the opposing force of thespring, the smaller ball is moved off its seat. This allows flow to create a similar pressure and action on the larger ball and spring. Flow continues on to the outlet of the check valve. If flow is reversed, flow force and

spring cause the large ball to be reseated. Any leakage around the large ball is blocked by the smaller ball that is firmly seated by spring.

Double Ball Check Valve Applications

Premier double ball check valves are designed for high pressureapplications where reverse flow/leakage must be kept to a minimum.Typical applications include engine, pump and compressor cylinder/packing lubrication and hydraulic systems. A relatively stiff spring in these check valves serves to increase the reliability of the circuit. |