|

Trelleborg特瑞堡密封系统汽车密封件Semiconductor Seals 应用Applications

Trelleborg特瑞堡汽车密封解决方案Automotive Sealing Solutions

精耕本地,辐射全球

汽车密封方案 "精耕本土,辐射全球 "

我们是为汽车OEM及其配件供应商提供先进密封方案的者。我们能够达到符合国际标准的行业要求——高产量、严质量、快交付。我们本地的工程研发技术团队与客户一起开发创新方案以应对汽车应用挑战。客户同时还能获得来自特瑞堡全球专业技术网络和战略分布的生产和物流中心的支持。 Trelleborg Sealing Solutions is a leading supplier of advanced sealing solutions to automotive Original Equipment Manufacturers (OEMs) and their component suppliers. We are able to match the high volume, stringent quality and advanced delivery demands of the industry on a global level. Our local engineering and development support teams work with customers to develop innovative solutions to meet automotive application challenges. Customers are supported by a global network of expertise and strategically located manufacturing and logistic centers worldwide.

密封方案满足汽车应用日益改变的需求

我们的方案满足车辆设计目标,例如轻量化,可回收和减低总成本。通过使用我们的方案,这些目标在不断变化的新技术上实现,例如电子控制,生物燃料,先进驾驶控制和精密燃料系统。

- Air Conditioning 空调

- Battery 电池

- Brakes 制动器

- Drivetrain & Transmission 传动系统和变速箱

- Electronic Control Unit (ECU) 电子控制单元(ECU)

- Fuel Systems 燃料系统

- Ride Control 行驶控制

- Safety Systems 安全系统

- Thermal Management 热管理

空调Air Conditioning

空调Air Conditioning

汽车的空调系统很复杂,许多O形圈贯穿于进出皮带驱动/电动压缩机的压力管路每个连接点都需要密封,以确保佳性能。A car's air conditioning system is complex, with a multitude of O-Ring's running throughout the pressure lines to and from a belt-driven/electric compressor. Every connection point needs to be sealed in order to ensure optimum performance.

密封空调系统要求Requirements for sealing air conditioning systems

- Operate under relatively high pressure 在相对高压下工作

- Fit into small installation spaces 适合小型安装空间

- Minimize wear to maximize seal life 尽量减少磨损,大限度地延长密封寿命

- Fulfills environmental legislation for zero leakage requirements 满足零泄漏要求的环境法规

密封解决方案Sealing Solution

定制设计的工程模压组件可以将多个零件合并到一个产品中,从而允许放置到空调系统中可用的有限空间中设计用于防止粘滑、延长密封和系统寿命的材料(空调使用受到限制)。Custom-designed engineered molded components can incorporate multiple parts into a single product, allowing placement into the limited space available in air conditioning systems. Materials engineered to prevent stick-slip, extend seal and system life where air conditioning use is limited.

Trelleborg Products

O形圈,特殊聚四氟乙烯旋转密封O-Ring , special PTFE rotary seals

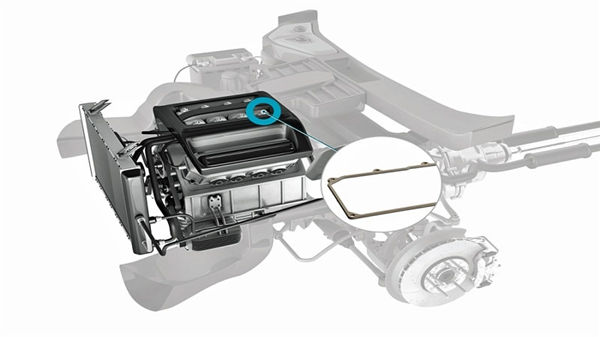

电池Battery

电池Battery

电池为车内的许多关键系统提供动力,如果没有电池,车辆将无法工作启动-停止选项以及混合动力系统,以尽量减少排放,对新电池技术具有挑战性的影响无论天气如何,司机们都希望第一次,每次都能发动汽车为了保证这种操作的可靠性,需要可靠的密封和电池通风。The battery provides the power to a number of critical systems in the car and without it, the vehicle is inoperable. Start-stop options as well as hybrid powertrains to minimize emissions, have challenging impacts on new battery technologies. Drivers expect to start their car whatever the weather, first time, every time. For that kind of operational dependability, reliable sealing and battery venting is needed.

蓄电池密封要求Requirements for sealing batteries

- Outstanding reliability 卓越的可靠性

- Extended seal life 延长密封寿命

- Operation in temperature extremes 在极端温度下运行

密封解决方案Sealing Solution

Ventseal是专门为电池等锁定容器应用而设计的它将密封和减压功能结合在一起。Ventseal is specially designed for locked container applications such as batteries. It combines a seal and pressure relief function all in one product.

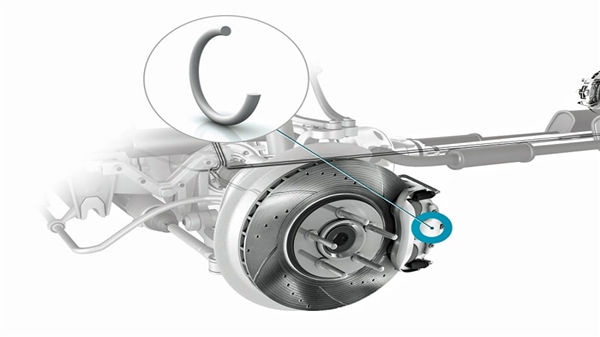

制动器Brakes

制动器Brakes

可能是所有汽车应用中安全的关键,在需要时,刹车将立即启动是至关重要的。Probably the most safety critical of all automotive applications , it is vital that when needed the brakes will activate instantaneously.

制动器密封要求Requirements for sealing brakes

- Consistent quality over high volumes 高容量的一致质量

- Media resistant to brake fluids 耐制动液介质

密封解决方案Sealing Solution

制动部件的质量由专门用于制动器专用混合线路的材料来保证。The quality of braking components are ensured with materials specially compounded on mixing lines dedicated to brakes.

Trelleborg Products

O形圈,定制模压组件O-Rings , Custom-molded components

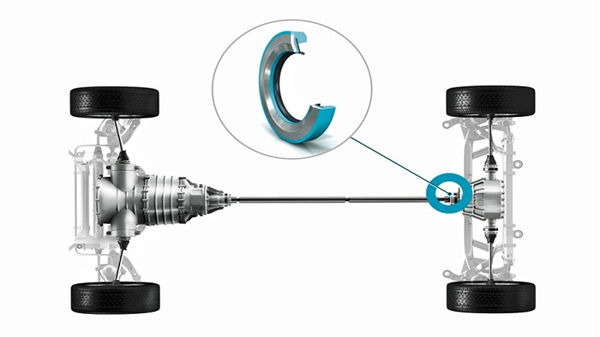

传动系统和变速箱Drivetrain & Transmission

传动系统和变速箱Drivetrain & Transmission

车辆的传动系和变速器使发动机的输出与驱动轮相适应发动机以相对较高的转速运转,变速器将转速降低到较低的车轮转速,从而在这一过程中增加扭矩。The drivetrain and transmission of a vehicle adapts the output of an engine to the drive wheels. Engines operate at relatively high rotational speeds and the transmission reduces that speed to the slower wheel speed, increasing torque in the process.

变速器密封要求Requirements for Sealing of Transmission

- Advanced rotary sealing solutions 先进的旋转密封解决方案

- Low friction to optimize the transmissions operation 低摩擦以优化变速器操作

- Outstanding wear resistance to extend transmission life 卓越的耐磨性,延长变速器寿命

- Resistance to the lubricants within the transmission 变速器内润滑剂的阻力

密封解决方案Sealing Solution

复杂的密封结构组合了许多先进的密封件,密封在润滑剂中,防止外部介质的侵入,并且由于无摩擦的低摩擦而在旋转应用中提供大性能Complex sealing configurations combine a number of advanced seals that seal in lubricants, prevent ingress of external media and provide maximum performance in rotary applications due to unrivaled low friction.

Trelleborg Products

Turcon Roto L , Slyd Ring , Back up Rings , O-Rings , Quad-Rings , Rubore seals

电子控制单元(ECU)Electronic Control Unit (ECU)

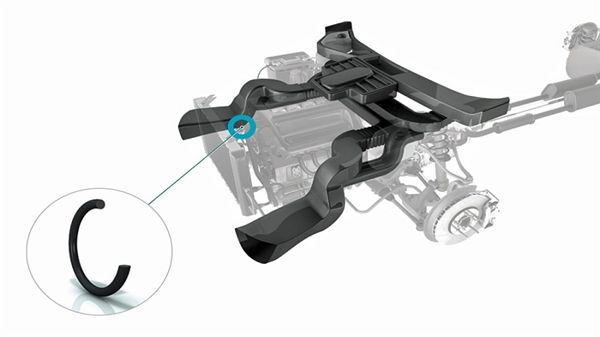

电子控制单元(ECU)Electronic Control Unit (ECU)

控制汽车关键功能的精密电子设备安装在电子控制单元的金属/塑料盒中通常位于发动机舱或其他受环境条件影响的区域,良好的密封至关重要,因为故障不是一个选项。Sophisticated electronics that control key functions of the car are housed in the metal/plastic box of an ECU. Often situated in the engine compartment or other areas subject to environmental conditions, good sealing is vital as failure is not an option.

ECUs密封要求Requirements for Sealing of ECUs

- Effective sealing of casings to reliably exclude any media that may affect sensitive electronics 外壳的有效密封,以可靠地排除任何可能影响敏感电子设备的介质

- Materials must stand up to the harsh conditions of the engine including temperature extremes and salt spray from the road 材料必须经得起发动机的恶劣条件,包括极端温度和道路上的盐雾

- Low media permeation (e.g. from transmission oil) 低介质渗透性(例如来自变速箱油)

密封解决方案Sealing Solution

Rubore盖密封件将密封件和电子控制单元盖集成到一个单元中,从而避免了昂贵的手动安装这将以较低的成本得到一个完美的解决方案。The Rubore Cover Seal integrates the seal and ECU cover into one single unit, thereby eliminating costly manual installation. This results in a perfect solution at a reduced cost.

此外,集成电子控制单元盖和密封件(如Rubore盖密封件所示),可减少零件数量,从而将物流、装配和管理成本降至低全弹性垫圈也可用于各种应用可进行内部渗透测试。In addition, integrating the ECU cover and the seal, as seen with the Rubore Cover Seal, reduces the number of parts therefore minimizing logistics, assembly and administration costs. Full elastomer gaskets are also available for a wide variety of applications. In-house testing of permeation is available.

Trelleborg Products

Engineered Molded Components , Rubore Seals , O-Rings

燃料系统Fuel Systems

燃料系统Fuel Systems

在极端温度和高压下运行,整个燃油系统(喷油器、共轨系统、燃油管路和燃油箱)都需要安全可靠的密封。Running at extreme temperatures and high pressures, secure and reliable sealing is required throughout the fuelling system – in the fuel injectors, the common rail system, the fuel lines and fuel tank.

燃油系统密封要求Requirements for sealing the fuel system

- Operate in a wide temperature range 在较宽的温度范围内工作

- Operate in a wide temperature range, very low to very high 在很宽的温度范围内工作,从很低到很高

- High pressure performance 高压性能

发动机高效运转的佳性能Optimized performance for efficient engine operation

密封解决方案Sealing Solution

多种密封件可用于燃油系统内的不同密封环境它们由专门的材料组成,经过精心设计,能够承受汽油、柴油和生物燃料以及极端的温度和压力。A wide range of seals are available for the different sealing environments within the fuel system. They are composed of specialized materials that have been engineered to withstand gasoline, diesel and bio-fuels, as well as temperature and pressure extremes.

Trelleborg Products

O-Rings , Engineered Molded Components , PTFE-based square cut rings, reinforced diaphragms

特殊低温材料Special low temperature material

特雷尔堡密封解决方案公司开发了一种用于燃油喷射应用的氟橡胶密封化合物,可在极低温度下工作。Trelleborg Sealing Solutions has developed a fluoroelastomer sealing compound for fuel injection applications that performs at extremely low temperatures.

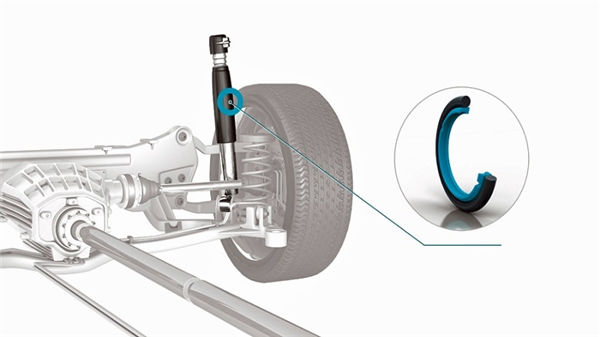

行驶控制Ride Control

行驶控制Ride Control

行驶控制系统的目标是将转向稳定性与良好的操纵特性相结合,同时大限度地提高乘客的舒适度。行驶控制系统包括悬架系统和减震器The objective of ride control systems is to combine steering stability with good handling characteristics while maximizing passenger comfort. The ride control system incorporates the suspension system and shock absorbers.

行驶控制密封要求Requirements for sealing ride control

- Low friction avoiding stick-slip 低摩擦避免粘滑

- Wear resistant 耐磨性

- Chemical resistant 耐化学性

Trelleborg Products

- Twin Seal : Very low friction rod seal 双密封:极低摩擦杆密封

- O-Rings : Low temperature flexibility O型圈:低温柔性

- Buffer Rings : Avoids metal-to-metal contact 缓冲环:避免金属与金属接触

- Back up Rings : Supports O-Rings in high pressure situations 支承环:在高压情况下支撑O形环

- Vane Seal: Specialty sealing 叶片密封:特种密封

安全系统Safety Systems

安全系统Safety Systems

今天的汽车包括各种各样的安全解决方案,以保护司机和乘客免受各种类型的碰撞这包括安装在前后座椅周围的安全气囊。Today's cars include a wide range of safety solutions to protect drivers and passengers from various types of collisions. This includes airbags installed to surround the front and rear seats.

气囊密封要求Requirements for sealing airbags

- Absolute quality throughout production over very high volumes 在高产量生产过程中的绝对质量

- Small seals with tiny flashfree holes 小密封件,带有微小的无火花孔

密封解决方案Sealing Solution

Trelleborg密封解决方案利用其在液态硅橡胶注射成型技术中的能力,在清洁和全自动化的过程中生产安全关键部件,完全无闪光。Trelleborg Sealing Solutions uses its capabilities in liquid silicone rubber injection molding technology to produce safety critical components, completely flash-less, in a clean and fully automated process.

Trelleborg Product

Sensor Cover

热管理Thermal Management

热管理Thermal Management

发动机在高温下运行并使某些发动机部件的寿命大化,发动机需要通过流过散热器的流体冷却。Engines operate at high temperatures and to maximize life of certain engine components, the engine needs to be cooled using fluid that flows through the radiator.

发动机冷却系统密封要求Requirements for sealing engine cooling systems

- Operate in combination with high rotational speeds and high pressure 在高转速和高压下工作

- Reliable low-friction sealing to reduce CO2 and save fuel 可靠的低摩擦密封,减少二氧化碳排放,节省燃料

- Withstand coolants and lubricants and operate in poor lubrication conditions 承受冷却剂和润滑剂,并在不良润滑条件下运行

密封解决方案Sealing Solution

采用Rubore密封技术或标准全弹性垫圈制造的专用密封件,提供定制解决方案,延长密封寿命。Specialized seals manufactured using the Rubore Seal technology or standard full elastomer gaskets, provide custom-made solutions with an extended seal life.

Trelleborg Products

Rubore Seals , Gaskets , O-Rings

Trelleborg 特瑞堡密封系统是全球领先的密封解决方案供应商。 我们的产品范围包括 O形圈 , 液压密封件 , 旋转密封件 , 油封 , 静态密封件 , 气动密封件 , 机械端面密封件等等。 Trelleborg Sealing Solutions is a leading global supplier of sealing solutions. Our range of products includes O-Rings , hydraulic seals , rotary shaft seals , oil seals , static seals , pneumatic seals , mechanical face seals and many more.

|