|

|

Trelleborg特瑞堡密封系统汽车密封件Semiconductor Seals 产品Products

Trelleborg特瑞堡汽车密封解决方案Automotive Sealing Solutions

精耕本地,辐射全球

汽车密封方案 "精耕本土,辐射全球 "

我们是为汽车OEM及其配件供应商提供先进密封方案的者。我们能够达到符合国际标准的行业要求——高产量、严质量、快交付。我们本地的工程研发技术团队与客户一起开发创新方案以应对汽车应用挑战。客户同时还能获得来自特瑞堡全球专业技术网络和战略分布的生产和物流中心的支持。 Trelleborg Sealing Solutions is a leading supplier of advanced sealing solutions to automotive Original Equipment Manufacturers (OEMs) and their component suppliers. We are able to match the high volume, stringent quality and advanced delivery demands of the industry on a global level. Our local engineering and development support teams work with customers to develop innovative solutions to meet automotive application challenges. Customers are supported by a global network of expertise and strategically located manufacturing and logistic centers worldwide.

汽车密封方案产品

"现今的乘用车制造中会使用到各种密封方案,O形圈就是其中一种。例如,减震器中承受高压的O形圈,电子控制单位中的精密垫圈,制动系统中至关安全的定制组件,用在喷油嘴中,承受极限温度、压力和侵蚀性介质的密封。

特瑞堡密封系统一直致力于发展其特殊设计密封以满足OEM及其配件供应商具挑战的需求。"

- 2-Component Parts 双组分零件

- Engineered Gaskets 工程垫圈

- HiSpinRotary Seals HiSpin?旋转密封

- L-CupL-Cup?型

- O-Rings O形圈

- Plug-in Seal 插入式密封

- PTFE Seals 聚四氟乙烯密封件

- RuboreSeals Rubore?密封件

- RuboreShims Rubore?垫片

- Skirted Piston

- TurconGlyd RingT Turcon?Glyd Ring?T系列

- TurconRoto L

- Twin Seal 双密封

- Valve Seal 阀门密封

- Ventseal Light 通风灯

双组分零件2-Component Parts

在专利的共注入工艺中,技术热塑性塑料和硅酮形成完全结合的高精度复合材料,形成双组分零件这一全自动化工艺使特雷堡密封解决方案成为液态硅橡胶(LSR)注射成型和二次加工能力的市场领导者如有要求,可在先进的洁净室生产双组分零件,这些洁净室提供完全无闪光的零件,用于安全关键应用。In a proprietary co-injection process, a technical thermoplastic and a silicone are formed into a fully bonded high-precision composite, creating the 2-component part . This fully automated process makes Trelleborg Sealing Solutions a market leader in Liquid Silicone Rubber (LSR) injection molding and 2-shot processing capabilities. If requested, 2-Component parts can be produced in state-of-the-art cleanrooms which offer completely flashless parts for use within safety critical applications.

汽车趋势影响液体硅橡胶(LSR)注模塑的Automotive trends affecting liquid silicone rubber (LSR) injection molding

- Lighter weight components 重量较轻的部件

- Increasingly sophisticated on-board electronic systems 日益复杂的车载电子系统

- Increasing driver safety features 增加安全驾驶功能

- Increasing driver comfort features 增加驾驶员舒适性功能

双部件解决方案的优点Benefits of 2-Component part solutions

- Greater design latitude 更大的设计纬度

- Feasibility of complex and micro components 复杂微构件的可行性

- Excellent sealing function of the composite 复合材料优良的密封性能

- Elimination of the risk and costs associated with secondary assembly 消除与二次装配相关的风险和成本

- Significantly reduced TCO (Total Cost of Ownership) 显著降低了TCO(总体拥有成本)

带LSR的双组分解决方案2-Component solutions with LSR

热塑性塑料与LSR的结合Thermoplastic in combination with LSR

LSR与选定范围的技术热塑性基材LSR co-injection or over-molding with a select range of technical thermoplastic substrates such as:

LSR in combination with LSR

将不同类型的硅酮共注射或二次成型到具有不同性能的复合材料零件中,例如:Co-injection or Overmolding of dissimilar types of silicone into composite parts with varying properties such as:

- Hardness 硬度

- Color 颜色

- Surface properties 表面特性

- Electro-conductive properties 导电性能

Engineered Gaskets

Working with our engineering teams, Trelleborg Sealing Solutions will support you in the development of customized engineered molded parts designed to suit your individual needs.

This may be a flat gasket of any dimension or a seal of complex geometry that may consolidate a number of products into one.

Our specially designed sealing solutions can provide significant benefits from a cost, function, manufacturing or performance perspective, providing you with a real competitive advantage.

Specially Engineered Gasket

ECU housing seals are specially designed to protect electronic components by sealing out transmission oil.

Highlights: The electrical flat ribbon cables are safely sealed from aggressive media

ECU Housing Gasket

ECU housing gaskets are specially designed for the given application situation and limits (requirements, maximal forces).

Highlights: Resistance to a range of different transmission oils, as well as special requirements for smoothness and cleanliness.

HiSpinRotary Seals

Manufactured to meet the needs of electric vehicle manufacturers, HiSpinrotary seals are specifically engineered for use in next-generation e-axles. A major technology in electric cars, e-axles combine the electric motor and gearbox in a single unit, which poses several unique sealing requirements:

- Conflicting conditions within the e-axle due to the shared housing

- Extreme rotation speeds

- Limited use of lubrication

- Seal material compatibility

HiSpinrotary seals deliver optimum performance at high rotational speeds under extreme temperature and lubrication conditions:

Learn more about HiSpinrotary seals for next-generation e-axles

L-Cup

The L-Cupis a single acting asymmetrical rod seal for a wide spectrum of applications.

The FEA optimized design provides outstanding sealing effectiveness and an improved hydrodynamic back pumping effect.

These features are made possible through minimized friction and reduced wear and tear in comparison to traditionally used lip seals.

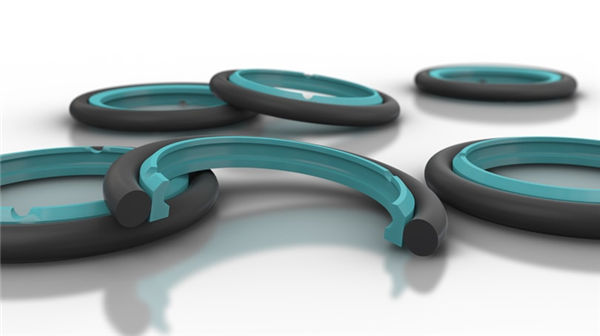

O-Rings

O-Rings offer the designer an efficient and economical sealing element for a wide range of static and dynamic applications.

The large selection of elastomer materials for both standard and special applications, allow the O-Ring to seal practically all liquid and gaseous media.

- Find out more about our large selection of O-Rings

Plug-in Seal

Specially developed radial seals that compensate for a wide range of tolerances. Innovative packaging with 3D printing technology is possible and ensures safe transport globally and speed up the manufacturing process in high volume productions.

Application:

Transmission control unit

PTFE Seals

PTFE based seals are always used if friction, media resistance, and space is an issue. Our Turcon-PTFE materials, possess a very low friction coefficient and simultaneously a good shape stability against high pressures. They are the ideal materials to design a low friction seal which works with high pressures, minimal space and has a high media resistant. As PTFE does not have an elastomer-elasticity, these kinds of seals are actuated by an O-ring. The O-ring gives the needed elasticity to compensate for misalignment. All of the rod seals have a back pumping effect which enables the seal to bring eventual leakage back to the pressure chamber against the system pressure.

Learn more about some of our patented Turcon Seals

- TurconGlydring

- L-Cup

- TurconDouble Delta

- TurconVL Seal

- TurconGlydringT

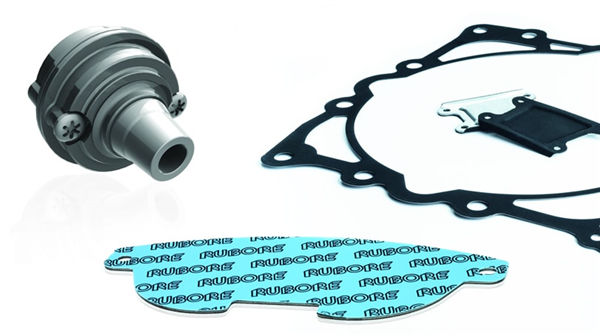

RuboreSeals

RuboreSeals:The Innovative Rubber-to-Metal Composite

RuboreSeals are produced through an advanced technology process which creates a sandwich composite material combining rubber, PTFE and metal layers.

Reduces weight: The dimensional stability of RuboreSeals allows for the design of thinner metal walls which leads to significant weight reductions when compared to full elastomer seals.

Lower handling costs: The stiffness of RuboreSeals saves assembly time and lessens logistic requirements, lowering overall manufacturing costs.

Compensates for roughness: The Ruboretechnology is an effective way to cope with uneven surfaces and pinholes on metal parts. This eliminates the need for surface finishing and significantly reduces process steps and costs.

Easy Assembly: Assembly speed is increased and made easier through the stiffening of the elastomer component by the metal layer.

More information on our Rubore Products

RuboreShims

Shims / Insulators

A unique rubber to metal composite material designed to solve noise and vibration problems.

Trelleborg Sealing Solutions Kalmar manufactures a wide range of noise damping shims / insulators that are used when endurance against thermal, chemical and mechanical stress is required. This is combined with out-standing sound damping, sealing, vibration insulation, compressibility and bonding capacity.

The materials consist of different combinations of layers of rubber, carbon steel, stainless steel, fibre glass, cold pressure adhesives, acrylic or silicone based and hot sensitive glues.

Shims / Insulators

Our unique rubber to metal composite materials for noise damping in disc brakes combine a number of valuable properties: vibration insulation, compressibility and excellent adhesion. The rubber composite materials are excellent for applications with demanding insulation for vibration and noise. The materials retain their integrity even when subjected to high pressure and high temperature. Noise damping components in brakes have to endure enormous strains and tension - extreme temperature, mechanical stress, salt, water, oil etc… Testing one and the same brake system in mountain and desert country, as well as in urban traffic and on the open highway is a costly and time consuming process.

We simplify this process by running tests in our fully computerized brake-noise dynamometers, equipped with unique acclimatiser. This allows us to literally test a brake in any climate in the world.

Read more technical information about our Noise Damping Shims.

Skirted Piston

TurconSkirted Piston Seal

The Skirted Piston, also known as Banded Piston, plays an important role in automotive shock absorbers. For optimal performance it must operate with low friction, high side-load capacity, wear resistance and reliable sealing.

Material and Design

Understanding the needs of automotive manufacturers, Trelleborg Sealing Solutions can offer Skirted Piston solutions custom-designed to a wide range of requirements with rapid turnaround times. This includes a size range of 25 to 50 mm and both single or double lip configurations. To note that the metal pistons are to be supplied by the customer, either with an existing groove profile or according to our recommendations. Skirted Piston discs are manufactured from world-renowned Turconpolytetrafluoroethylene (PTFE) based material, specially formulated and proven for use in Skirted Piston applications..

Production Solution Provider

Uniquely positioned to offer service with a global network and local support, Trelleborg Sealing Solutions can provide a range of different production options giving customers assembly and purchasing savings, increased product reliability and optimized supply chains. Lower volumes can be handled by us on in-house developed machines, while for higher volumes these machines can also be supplied to the customer.

TurconGlyd RingT

The Turcon?Glyd RingT is a double acting symmetrical seal which differs from a standard Glyd Ringdue to its trapezoidal cross section and concave edges. This improved design permits a specific tilting of the seal to ensure that the maximum compression is always applied on the areas with the highest pressure, thereby providing an optimal solution for leakage control.

On areas of low pressure, there is no compression or shear loads on the seal. This, together with the concave shape of the seal, enables a higher radial clearance and reduces the danger of gap extrusion. In addition, the Turcon?Glyd Ring?T provides excellent friction characteristics, no stick-slip and minimal break out force.

TurconRoto L

Extended Seal Life and Low Friction

The TurconRoto L seal is the first ever active seal and is engineered to extend seal life on axle systems. Uniquely, it only seals when sealing is required. This reduces friction to lower fuel consumption and thereby conserves energy. It is ideal for sealing in drivetrain applications , such as the Central Tire Inflation Systems (CTIS).

TurconRoto L combines a PTFE based sealing lip with a rubber jacket and a stable shape-forming metal part. The seal's patented design ensures that, for the majority of the time, the sealing lip is held lightly against the sealing surface until pressure is activated. This unique design offers features and benefits that no other seal can.

Features and Benefits:

- Operates only when required * Extended seal life

- Total system life sealing

- Low friction

- Minimal friction when not pressurized

- Capable of constant activation

- Saves energy

- Improved safety

- Minimizes wear

Less pressure, less friction

TurconRoto L reduces shaft run-in significantly. A standard radial oil seal has a run-in of 10.1 μm after 168 h. In comparison, the TurconRoto L has a run in of 4.59 μm after 780 h, resulting in a seal life that is at least four times longer than a standard radial oil seal.

Twin Seal

Twin seals are high performance rod/piston seals with a PTFE profile used in dynamic hydraulic applications with pressures up to 200 bar.

Highlights

In ride control applications , they are effective in reducing friction and extending seal life,thereby providing a no "stick-slip" effect, maximal performance, superior ride and damping functions.

Valve Seal

The Valve seal is an optimized sealing element designed through FEM calculations for high pressure fuel pump applications. The Valve seal regulates the rate of the fuel flow.

Application:

High pressure fuel pump

Ventseal Light

Ventseal-Light combines a seal and pressure relief valve function all in one product. It is used for ventilation of locked containers such as an Absorbent Glass Mat (AGM) battery for start-stop technology, fluid reservoirs or sealed beam headlamp units.

Trelleborg 特瑞堡密封系统是全球领先的密封解决方案供应商。 我们的产品范围包括 O形圈 , 液压密封件 , 旋转密封件 , 油封 , 静态密封件 , 气动密封件 , 机械端面密封件等等。 Trelleborg Sealing Solutions is a leading global supplier of sealing solutions. Our range of products includes O-Rings , hydraulic seals , rotary shaft seals , oil seals , static seals , pneumatic seals , mechanical face seals and many more.

|