|

|

Trelleborg特瑞堡密封系统航空密封件Aircraft Seals

特瑞堡密封系统公司是航空密封解决方案的 供应商,其历史可以追溯到60多年前。 Dowty,Palmer-Chenard,Shamban,Airframe Seals和Impervia都是特瑞堡密封系统产品组合中的品牌。 Trelleborg Sealing Solutions is the leading supplier of sealing solutions to the aerospace industry with a history that goes back over 60 years. Dowty, Palmer-Chenard, Shamban, Airframe Seals and Impervia are all brands within the Trelleborg Sealing Solutions portfolio.

我们的产品几乎用于所有主要的飞机项目,并且通常被领先的飞机制造商和OEM客户指定为关键应用的密封解决方案的提供方。 Almost every major program.

Our products are used in almost every major aircraft program and are commonly specified by leading aircraft manufacturers and OEM customers as sealing solutions on a wide range of critical applications.

航空航天用高性能密封件High Performance Seals For Aerospace Applications

作为全球航空密封解决方案供应市场的领导者,Trelleborg密封解决方案拥有60多年的行业经验,能够为大多数应用提供佳的密封

As a global market leader in the supply of aerospace sealing solutions, with over 60 years of experience in the industry, Trelleborg Sealing Solutions can provide the optimum seal for the majority of applications.

所用材料适用于从双座轻型飞机到重型远程商用客机,从直升机到航天器和卫星的任何设备作为聚合物技术的专家,我们几十年来一直是开发用于航空航天应用的聚合物化合物的领先者。The materials used are suitable to be fitted on anything from a two-seater light aircraft to heavy-duty long-range commercial airliners, from helicopters to spacecraft and satellites. As specialists in polymer technology, we have for decades been a world-leader in the development of polymeric compounds for use in aerospace applications.

适合的材料The right materials for the job

Trelleborg密封解决方案不仅在内部开发和制定其航空航天材料,而且在应用材料技术领域获得了重要技能,使我们能够推荐涂层和表面光洁度密封件可以单独手工制作、自动成型、织物增强或粘合到金属部件上。Not only does Trelleborg Sealing Solutions develop and formulate its aerospace materials in-house, it has also acquired significant skills in the field of applied materials technology enabling us to recommend coatings and surface finishes. Seals can be individually hand-fabricated, automatically molded, fabric-reinforced or bonded to metallic components.

有许多标准适用于航空航天工业本节列出的是关键的。There are a large number of standards that apply to the aerospace industry. Listed in this section are the key ones.

标准机构Standard authorities

所有以AS(航空航天标准)或ARP(航空航天推荐规程)为前缀的标准均由美国汽车工程师学会(SAE International)发布特雷堡密封解决方案是SAE工作的积极贡献者可从美国汽车工程师学会获得SAE标准的副本。All standards prefixed with either AS (Aerospace Standard) or ARP (Aerospace Recommended Practice) are issued by SAE International (Society of Automotive Engineers) in the US. Trelleborg Sealing Solutions is an active contributor to the SAE work. Copies of SAE standards may be obtained from the Society of Automotive Engineers.

这是包括航空航天在内的各种动力车辆工程的标准发展组织此外,MIL标准涵盖军用飞机,由美国国防部发布。This is a standards development organization for the engineering of powered vehicles of all kinds including aerospace. In addition, MIL standards cover military aircraft and are issued by the US Department of Defense.

航空航天标准Aerospace Standards

ARP1234, Revision B

密封圈设计,弹性O形密封圈,轴向静止,无支撑环Gland Design, Elastomeric O-Ring Seals, Static Axial, Without Back-Up Rings

为静态轴向弹性O形圈密封圈提供标准尺寸标准,无支撑环。本标准补充了ARP 1231,“压盖设计,弹性O形密封圈,一般注意事项。”标准与MIL-G-5514中的标准相似,但不完全相同。Provides standardized dimensional criteria for static axial elastomeric O-Ring seal glands, without Back-up Rings. This standard supplements ARP 1231, “Gland Design, Elastomeric O-Ring Seals, General Considerations.“ The criteria are similar, but not identical, to those in MIL-G-5514.

ARP5316

在硬件组装之前,储存弹性体密封件和密封组件,其中包括弹性体元件,阐述了在将密封组装成硬件组件之前,对弹性密封件和密封组件(包括弹性元件)的数据记录程序、包装和存储的一般要求。

Storage of Elastomer Seals and Seal Assemblies Which Include an Elastomer Element Prior to Hardware Assembly

Addresses the general requirements for data recording procedures, packaging and storing of elastomeric seals and seal assemblies which include an elastomeric element prior to the seal being assembled into hardware components.

包装要求是受控储存程序的一个组成部分,并提供了从制造到组装成组件的产品标识。The requirement for packaging is an integral part of the controlled storage procedure and provides a means of positive product identity from the time of manufacturing to the time of assembly into a component.

AS4088

Aerospace Rod Scraper Gland Design Standard

Defines gland dimensions for rod scrapers. Gives specifications for rod diameters from to 15 inches/ six to 394 mm, inclusive corresponding to AS568 O-Ring Dash No. sizes -108/-111, -206/-222, -325/-349 and -425/-460. The gland details provide more space than MS33765 and are sufficient to fit more efficient and reliable exclusion devices.

AS4052

航空航天杆式刮板压盖设计标准Gland Design: Scraper, Landing Gear, Installation

包括用于在起落架减震支柱下端安装刮油环/刮油环的替代压盖设计,以排除污染物。Covers an alternate gland design for the installation of scraper/ wiper rings in the lower end of landing gear shock struts for the purpose of contaminant exclusion.

活塞杆直径、压盖内径、槽侧角和表面光洁度均由AS4716规定,但压盖外挡土墙直径有所变化压盖有一个缩小的大气压盖唇口和几何形状的异型铅,以允许安装聚四氟乙烯护套金属弹簧激励刮刀。Piston rod diameters, gland internal diameters, groove sidewall angles and the surface finish are all defined by AS4716, but the gland outer retaining wall diameter is changed. The gland has a reduced atmospheric gland lip and profiled lead in geometry to allow for a PTFE jacket metal spring-energized scraper to be installed.

AS4716

压盖设计、O形密封圈和其他弹性密封件Gland Design, O-Ring and Other Elastomeric Seals

提供静态和动态应用弹性密封压盖的标准化压盖设计标准和尺寸。Provides standardized gland design criteria and dimensions for elastomeric seal glands for static and dynamic applications.

压盖专门设计用于使用SAE AS 568尺寸的O型环(相关2级公差)的应用,压力超过1500psi/10.3Mpa时,使用一个或两个防挤压支承环,压力低于1500psi/10.3Mpa时,无支承环虽然本规范涵盖了与标准尺寸O型环一起使用的基本设计标准和建议,但这些密封套也可与其他弹性体和聚四氟乙烯基密封和填料一起使用。The glands have been specifically designed for applications using SAE AS 568 size O-Rings, with related class 2 tolerances, at pressures exceeding 1,500psi/ 10.3 MPa utilizing one or two anti-extrusion Back-up Rings and applications at pressures under 1,500psi/ 10.3 MPa without Back-up Rings. While this specification covers the basic design criteria and recommendations for use with standard size O-Rings, these glands are also for use with other elastomeric and PTFE based seals and packings.

AS4832

压盖设计:定制压缩式密封的标称3/8英寸横截面Gland Design: Nominal 3/8 Inch Cross Section for Custom Compression Type Seals

提供标称3/8英寸/0.364 mm横截面压盖的压盖细节,压盖长度建议用于压缩型密封,带有直径在8至20英寸/203至508 mm范围内的两个支承环。Offers gland details for a nominal 3/8 inch/ 0.364 mm cross section gland with proposed gland lengths for compression-type seals with two Back-up Rings over a range of eight to 20 inches/ 203 to 508 mm in diameter.

建议采用类似于AS568A的仪表盘编号系统。密封配置和设计不属于本文件的一部分该压盖用于定制的压缩式密封,包括但不限于O型环、T型环、D型环等。A dash number system is proposed similar to AS568A. Seal configurations and design are not a part of this document. This gland is for use with custom compression-type seals including, but not limited to O-Rings, T-Rings, D-Rings, etc.

材料和技术Materials and Technology For Aerospace Industry

规范和批准Specifications and Approvals

对于航空航天应用,许多设计是复合密封件,其中弹性体元件是密封件的组成部分因此,必须仔细控制弹性体膨胀、成型收缩、压缩永久变形、介质相容性和公差等参数。For aerospace applications many designs are composite seals, with an elastomer element as an integral part of the seals. It is therefore important that parameters such as elastomer swell, shrinkage during molding, compression set, media compatibility and tolerances are carefully controlled.

通过稳定的工艺和我们实验室100%的批量测试,我们确保材料的制造符合Trelleborg密封溶液的规格作为美国政府和航空航天工业支持计划的一部分,一些材料也被批准用于合格产品清单(QPL)Through stable processes and 100 percent batch testing in our laboratories, we make sure that the materials are manufactured to Trelleborg Sealing Solutions specifications. A number of materials have also been approved for a Qualified Products List (QPL) as part of US government and Aerospace Industry support programs.

化学相容性Chemical Compatibility

弹性体材料比其他密封化合物对流体更敏感化学反应会损坏密封,影响物理性能特别是在液压应用中,为给定的液压流体选择佳弹性体材料至关重要不仅要考虑使用的机油,还要考虑添加剂,因为这些添加剂会导致不良行为可能需要在高温下进行浸泡试验,以验证应用中的性能Elastomer materials are more sensitive to fluids than other sealing compounds. Chemical reaction can cause damage to the seal, affecting physical properties. Specifically in hydraulic applications, selection of the optimum elastomer material for a given hydraulic fluid is critical. Not only must the oil used be taken into account but also the additives, as these can cause adverse behaviour. It may be necessary to conduct a soak test at elevated temperature in order to verify the performance in application.

温度范围Temperature Range

Turel化合物可在-73°C至+260°C/-100°F至+500°F的温度下工作。因此,大多数化合物将满足AS4716 II型系统的温度要求,规定为-54°C至+135°C/-65°F至+275°F。使用弹簧通电的Variseal可进一步扩大温度范围此外,对于高温应用,IsolastJ8325的工作温度高达+325°C/+617°F。Turel Compounds are available to operate in temperatures from -73°C to +260°C / -100°F to +500°F. Most will therefore meet the temperature requirements of AS4716 type II systems, specified as -54°C to +135°C / -65°F to +275°F. The use of spring- energized Variseal can expand the temperature range even further. In addition, for high-temperature applications, Isolast J8325 has an operating temperature up to +325°C / +617°F.

温度循环Temperature Cycling

温度循环对弹性体密封的影响会导致压缩永久变形这意味着弹性体材料随着时间的推移失去弹性对于Turel材料,如果指定用于工作温度在指定参数范围内的应用,则该影响保持在可接受的小值低温动态循环极限随弹性体类型而变化。The effect of temperature cycling on elastomer seals can result in compression set. This means that the elastomer material loses its elasticity over time. For Turel materials, this effect is kept to an acceptable minimum if they are specified for applications with operation temperatures within the indicated parameters. The low-temperature dynamic cycling limits vary according to elastomer type.

低温Cold Temperatures

特瑞堡密封溶液中的弹性体材料是专门设计的,以在寒冷条件下获得大的性能。Elastomer materials from Trelleborg Sealing solutions are specifically engineered to give maximum performance in cold conditions.

在寒冷环境中,弹性体材料收缩约是钢的十倍。材料在低温下变硬,失去弹性。当通过下限时,它达到玻璃化转变阶段,当它变得极其脆弱当温度再次升高时,物理性质将恢复增加挤压可以改善低温性能。Elastomer materials contract approximately ten times more than steel in cold environments. The material becomes stiffer and loses its flexibility at cold temperatures. When passing the lower limit it reaches the glass transition stage, when it becomes extremely brittle. Physical properties will recover when temperatures elevate again. Increased squeeze can improve performance at low temperatures.

高温Hot Temperatures

如果超过温度上限,弹性体材料就会软化并失去物理性能物理性能不会恢复,密封件将承受永久压缩永久变形压缩永久变形也随弹性体所接触介质的类型而变化持续暴露在高于推荐温度的环境中可能会永久损坏密封件。Elastomer materials soften and lose their physical properties if the upper temperature limit is exceeded. Physical properties will not recover and the seal will take on a permanent compression set. The compression set also varies with the type of media to which the elastomer is exposed. Continuous exposure to temperatures higher than those recommended can permanently damage the seal.

表面速度Surface Speed

通常,与弹性体密封接触的动态表面速度应保持在9.8 ft/s/3 m/s以下,以避免对弹性体造成损坏。In general, the speed of the dynamic surface in contact with an elastomer seal should be kept below 9.8 ft/s / 3 m/s to avoid damage to the elastomer.

老化Aging

大的推荐储存和货架时间可以在我们的航天密封系统产品目录和工程指南中看到。这些值仅在弹性体在控制条件下储存在防光和密封包装中时有效。The maximum recommended storage and shelf time can be seen in our Aerospace Sealing Systems Product Catalog and Engineering Guide. These values are only valid if the elastomer is stored under controlled conditions in light-proof and airtight packaging.

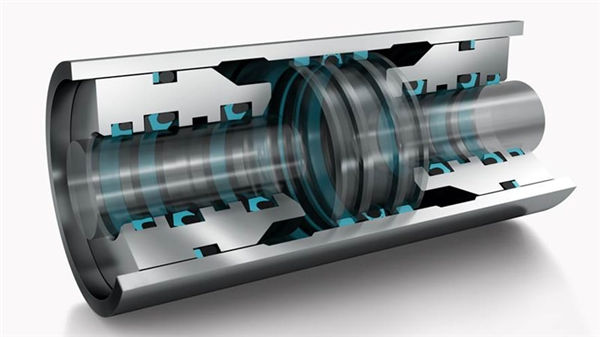

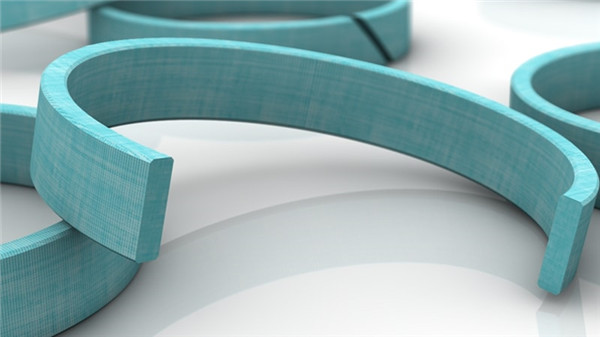

OrkotSlydring和轴承Orkot Slydring & Bearings

Orkot材料由特殊的热塑性树脂制成,浸渍有精细编织纤维的织物复合材料。Orkot materials are made of special thermoplastic resin impregnated with a fabric composite of fine weave fibers.

在需要重型轴承系统的地方,由Orkot材料制成的Slydring轴承是全球公认的解决方案它们具有优异的使用寿命、高抗压强度、耐热性和耐化学性以及极低的摩擦特性。Where heavy-duty bearing systems are required, Slydring bearings made from Orkot material are an established solution worldwide. They offer excellent service life, high compressive strength, heat and chemical resistance along with very low friction characteristics.

OrkotSlydring提高系统寿命和可靠性Orkot Slydring improves system life and reliability

对于存在高侧负荷的动态液压系统中的杆和活塞应用,OrkotSlydring轴承可以充当导环,以保持往复和旋转部件的正确定位和同心度使用OrkotSlydring可防止运动部件之间的金属对金属硬件接触,并消除硬件的刻痕和磨损,从而提高系统寿命和可靠性。For rod and piston applications in dynamic hydraulic systems where high side loads are present, Orkot Slydring bearings can act as guide rings to maintain correct positioning and concentricity of reciprocating and rotating components. Use of Orkot Slydring prevents metal-to-metal hardware contact between moving parts and eliminates scoring and fretting of hardware, resulting in improved system life and reliability.

Turcon

Turcon系列由基于优质聚四氟乙烯(PTFE)氟聚合物树脂的专有材料组成添加填料以提高材料性能。The Turcon range consists of proprietary materials based on premium-grade Polytetrafluoroethylene (PTFE) fluoropolymer resins. Fillers are added to enhance material properties.

世界上大的聚四氟乙烯密封件制造商The world's largest manufacturer of PTFE based seals

Trelleborg密封解决方案公司是世界上大的此类密封材料制造商,没有其他密封供应商能提供如此广泛的等级所有这些都是我们在欧洲、美国、南美和亚洲的工厂生产的。Trelleborg Sealing Solutions is the world's largest manufacturer of seals in this type of material, and no other sealing supplier can offer such a wide range of grades. All of these are produced at our own facilities in Europe, US, South America and Asia.

Turcon的特性The characteristics of Turcon

- Low Friction 低摩擦

- Chemically inert in virtually all media 几乎在所有介质中都是化学惰性的

- Able to operate in temperatures from -196°C to +260°C / -320°F to +500°F and will endure temperature spikes of up to +360°C / +680°F 能够在-196°C至+260°C/-320°F至+500°F的温度下工作,并能承受高达+360°C/+680°F的温度峰值

- Not altered or adversely affected by cycling temperatures. 不受循环温度改变或不利影响的。

- Does not contain plasticizers or any other ingredients which could degrade at temperatures below +300°C / +572°F. 不含增塑剂或任何其他可能在低于+300°C/+572°F的温度下降解的成分。

- Speed of the dynamic surface in contact with the seal can go up to 15 m/s / 49.2 ft/s 与密封件接触的动态表面速度可达15 m/s/49.2 ft/s

- Will not become brittle or degrade when exposed to severe-weathering conditions such as heat, light, water or salt spray 暴露在恶劣的风化条件下(如热、光、水或盐雾)不会变脆或退化

- High wear resistance 高耐磨性

- Doesn't absorb fluids to a significant level 不会吸收大量液体

- Excellent electrical properties 优异的电性能

- Can be safely used in a vacuum 可在真空中安全使用

- Will not sustain fire in pure oxygen 在纯氧中无法维持火焰

Turel & Isolast

Turel系列弹性体经过特殊设计,可满足航空航天行业的挑战性要求它包括丁腈橡胶(NBR)、氟碳橡胶(FKM)、三元乙丙橡胶(EPDM)、氢化丁腈橡胶(HNBR)、氟硅橡胶(FVMQ)和硅橡胶(Q)。The Turel range of elastomers is specifically engineered to meet the challenging requirements of the aerospace industry. It includes Nitrile (NBR), Fluorocarbon (FKM), Ethylene Propylene Diene Monomer (EPDM), Hydrogenated Nitrile Butadiene Rubber (HNBR), Fluorosilicone (FVMQ) and Silicone Rubber (Q).

除高温应用外,建议使用Isolast全氟弹性体(FFKM)这些材料在使用方面非常灵活,适合于大量的应用。In addition for high-temperature applications, an Isolast perfluoroelastomer (FFKM) is recommended. These materials are extremely flexible in their use and are suitable for a large number of applications.

丁腈橡胶NBR (Nitrile Butadiene Rubber)

Turel标准等级:NE、NG、NB、NZTurel Standard Grades: NE, NG, NB, NZ

丁腈橡胶主要用于矿物油和润滑脂丁腈橡胶的性能主要取决于其丙烯腈(CAN)含量,范围在18%到50%之间一般来说,材料具有良好的机械性能,工作温度在-30°C/-22°F和+100°C/+212°F之间。短时间内,丁腈橡胶可承受+120°C/+248°F的高温,特殊配方的丁腈橡胶可使用-60°C/-76°F的高温NBR is primarily used with mineral-based oils and greases. The properties of NBR depend mainly on their acrylonitrile (CAN) content, which ranges between 18 and 50 percent. In general the materials have good mechanical properties with operating temperatures ranging between -30°C / -22°F and +100°C / +212°F. For short periods of time NBRs can withstand up to +120°C / +248°F and specially formulated NBR can be used down to -60°C / -76°F

氟橡胶FKM (Fluorocarbon Rubber)

Turel标准等级:FK、FT、FG、FLTurel Standard Grades: FK, FT, FG, FL

FKM主要用于高温下的矿物油和润滑脂取决于结构和氟含量,FKM材料在其耐化学性和冷弹性方面可以不同。FKM以其不可燃性、低透气性、优异的抗臭氧、耐候性和耐老化性而闻名FKM材料的工作温度在-20℃/-4℉和+200℃/+392℉之间。在短时间内,FKM可承受高达+230℃/+446℉的温度,特别配制的FKM可使用低至-35℃/-31℉。FKM is primarily used with mineral-based oils and greases at high temperatures. Depending on structure and fluorine content, FKM materials can differ with regards to their chemical resistance and cold-flexibility. FKM is particularly known for its non-flammability, low gas permeability, and excellent resistance to ozone, weathering, and aging. The operating temperatures of FKM materials range between -20°C / -4°F and +200°C / +392°F. For short periods of time FKMs can withstand up to +230°C / +446°F and specially formulated FKM can be used down to -35°C / -31°F.

三元乙丙橡胶EPDM (Ethylene Propylene Diene Monomer)

Turel标准等级:EP、EHTurel Standard Grades: EP, EH

三元乙丙橡胶通常用于以乙二醇和热水为基础的制动液三元乙丙橡胶材料具有良好的耐热性、耐臭氧性和耐老化性此外,它们还具有高弹性、良好的低温性能以及良好的绝缘性能EPDM is often used in applications with brake fluids, based on glycol, and hot water. EPDM materials give good heat, ozone, and aging resistance. In addition they also exhibit high levels of elasticity, good low temperature behavior as well as good insulating properties.

三元乙丙橡胶材料的工作温度在-45°C/-49°F和+150°C/+302°F之间。在短时间内,它们可以承受高达+347°F/+175°C的温度。硫固化类型的工作温度降低到-45°C/-49°F和+120°C/+248°F之间,在短时间内,三元乙丙橡胶可以承受高达+150°C/+302°F的温度。The operating temperatures of EPDM materials range between -45°C / -49°F and +150°C / +302°F. For short periods of time they can withstand up to +347°F/+175°C. Operating temperatures of sulfur cured types are reduced to between -45°C / -49°F and +120°C / +248°F, for short periods of time EPDMs can withstand up to +150°C / +302°F.

氢化丁腈橡胶HNBR (Hydrogenated Nitrile Butadiene Rubber)

HNBR由于具有优异的耐磨性,常被用于高温应用丁腈橡胶(NBR)的选择加氢制备了HNBR材料与此类似,HNBR橡胶的性能取决于其丙烯腈(ACN)含量(在18%到50%之间)及其饱和度HNBR具有良好的力学性能。HNBR is often used in high-temperature applications due to excellent abrasion resistance. HNBR materials are produced by selective hydrogenation of the NBR groups. Like these, the properties of the HNBR rubber depend on their acrylonitrile (ACN) content which ranges between 18 and 50 percent as well as on the degree of its saturation. HNBR has good mechanical properties.

HNBR材料的工作温度在-30°C/-22°F和+140°C/+284°F之间。在短时间内,HNBR可承受高达+160°C/+320°F的矿物油和润滑脂接触特殊配方可在-40°C/-40°F下使用。The operating temperatures of HNBR materials range between -30°C / -22°F and +140°C / +284°F. For short periods of time HNBRs can withstand up to +160°C / +320°F in contact with mineral oils and greases. Special formulations can be used down to -40°C / -40°F.

氟硅橡胶FVMQ (Fluorosilicone Rubber)

Turel标准等级:LA、LB、LD、LFTurel Standard Grades: LA, LB, LD, LF

FVMQ常用于军事应用和燃料系统中FVMQ材料具有优异的耐热性、冷弹性、介电性能,特别是良好的耐氧和臭氧性能。FVMQ is often used in the military applications and fuel systems. FVMQ materials give excellent heat resistance, cold flexibility, dielectric properties and especially good resistance to oxygen and ozone.

根据材料的不同,工作温度在-60℃/-76℉和+200℃/+392℉之间。在短时间内,FVMQ可承受高达+230℃/+446℉的温度。特殊配方可使用低至-90℃/-130℉。Depending on the material, operating temperatures range between -60°C / -76°F and +200°C / +392°F. For short periods of time FVMQs can withstand up to +230°C / +446°F. Special formulations can be used down to -90°C / -130°F.

Q(硅橡胶)Q (Silicone Rubber)

Turel标准等级:SLTurel Standard Grades: SL

硅橡胶常用于垫圈、模压密封件、机身、空气动力和发动机密封件该材料具有优异的耐热性、冷弹性、介电性能,特别是良好的耐氧和臭氧性能。Silicone rubber is often used in gaskets, molded seals, airframe, aerodynamic and engine seals. The material gives excellent heat resistance, cold flexibility, dielectric properties and especially good resistance to oxygen and ozone.

根据材料的不同,工作温度在-60℃/-76℉和+200℃/+392℉之间。短时间内,硅橡胶可承受高达+230℃/+446℉的温度。特殊类型的可使用低至-90℃/-130℉。Depending on the material, operating temperatures range between -60°C / -76°F and +200°C / +392°F. For short periods of time Silicone Rubbers can withstand up to +230°C / +446°F. Special types can be used down to -90°C / -130°F.

FFKM (Perfluoroelastomer)

Isolast标准等级:J8325 Isolast Standard Grades: J8325

FFKM的应用主要存在于飞机发动机和所有环境恶劣或高温的应用中。Applications for FFKM can be mostly found in aircraft engines and in all applications with either aggressive environments or high temperatures.

全氟弹性体在高温下几乎对所有介质都具有抵抗力,并且表现出低膨胀性。Perfluoroelastomers are resistant to virtually all media at elevated temperatures and demonstrate low swelling.

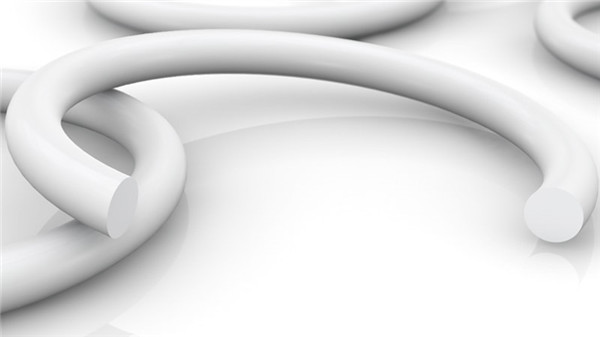

Zurcon

Zurcon系列材料由高模量化合物组成它们被推荐用于支撑和保护密封元件免受高压、大间隙和五金件变形等条件的影响。The Zurcon range of materials is made up of high modulus compounds. They are recommended to support and protect sealing elements from conditions such as high-pressure, large clearance gaps and hardware deflections.

出色的表现Exceptional Performance

这些材料具有很高的抗蠕变和良好的剪切性能,在支承环结构中提供了更好的挤压保护。These materials have high creep resistance and excellent shear properties giving superior protection from extrusion in Back-up Ring configurations.

航空航天标准Aerospace Standards

材料和技术Materials and Technology

Orkot and Slydring

Turcon

Turel & Isolast

Zurcon

有关航空密封解决方案的更多信息:

Trelleborg 特瑞堡密封系统是全球领先的密封解决方案供应商。 我们的产品范围包括 O形圈 , 液压密封件 , 旋转密封件 , 油封 , 静态密封件 , 气动密封件 , 机械端面密封件等等。 Trelleborg Sealing Solutions is a leading global supplier of sealing solutions. Our range of products includes O-Rings , hydraulic seals , rotary shaft seals , oil seals , static seals , pneumatic seals , mechanical face seals and many more.

|