|

Electronic Data Devices Turbine Flow Meters

EDD液体涡轮流量计

EDD 600 流量计EDD-600 FLOW Meters

Electronic Data Devices TOTALIZER RATE INDICATOR积算显示器

EDD-600

Digital Battery Powered totalizer数字电池计算仪

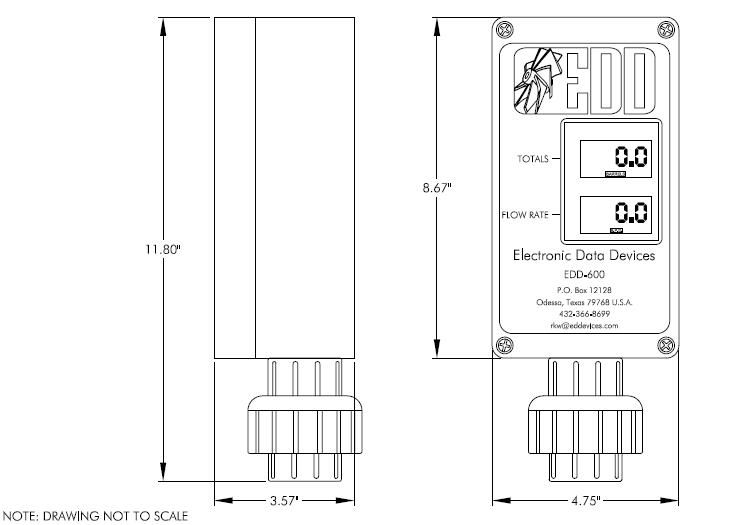

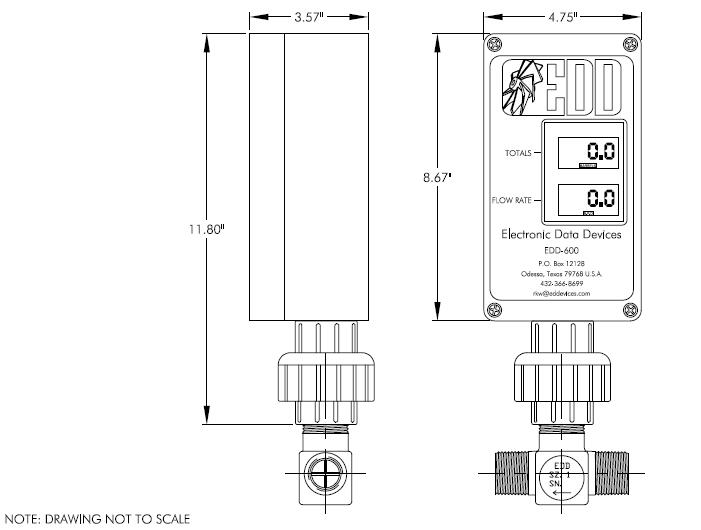

EDD-600型涡轮流量计是一个独立的计算和流量指示器,直接设计用于安装在涡轮机上,或者可以远程安装可选的硬件。The EDD-600 is a self-contained totalizer and flow rate indicator designed to mount directly on the turbine meter or may be remotely mounted with optional hard ware.

采用先进的低功耗CMOS集成电路和液晶显示器,电池寿命长By using state of the art low power CMOS intergrated circuits and liquid crystal displays, long battery life is attained

EDD 600 流量计 资料下载

规格Specifications

| Power |

4 C Batteries |

Battery Life |

2-4 Years |

| Flow Rate |

Diaital 6 Digit |

Flow Rate Units |

Specified by customer |

| Totalizer |

Digital 6 Digit |

Totalizer Units |

Specified by customer |

| Totalizer Reset |

With optional switch |

Divisor Capability |

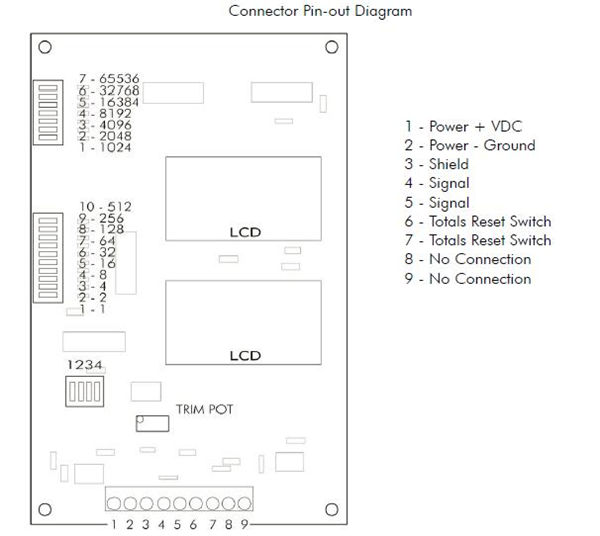

From 1- 131071 |

| Accuracy |

±1 Count |

Mounting |

Directly on meter |

| Temperature Range |

20°to155°F |

Housing |

Polyester Weatherproof |

| Input Frequency |

0-2500Hz |

Input Amplitude |

20-5000mVpp |

| Power |

4 Alkaline or Optional 2 Lithium |

| Battery Lite |

2-4 Years |

| Flow Rate |

Digital 6 Digit |

| Flow Rate Units |

Specified by customer |

| Totalizer |

6 Digit |

| Totalizer Units |

Specified by customer |

| Totalizer Reset |

With optional switch |

| Divisor Capability |

From 1-131071 |

| Accuracy totalizer |

±1 Count |

| Mounting |

Directly on meter |

| Temperature Range |

20°to155°F |

| Housing |

Polyester Weatherproof |

| Input Frequency |

0-2500Hz. |

| Input Amplitude |

20-5000 Mv. peak to peak |

EDD Standard Threaded Turbine Flow Meters标准螺纹涡轮流量计

特征Features

- Affordable

- Repeatability is within +/-0.1% of indicated flow throughout linear range 在整个线性范围内,重复性在指示流量的±0.1%范围内

- Linearity is within +/-1% of the k-factor throughout the linear range 在整个线性范围内,线性度在k系数的+/-1%范围内

- Flow Meters are available in a variety of end connections. 流量计有多种端部连接

规格Specifications

| Range of Operation |

Size |

Gal/Min |

BBL/Min |

BBL/Day |

Pulses/Gal |

Max. Pulses/Sec |

3/8" |

.3-3 |

.007-.07 |

10-100 |

22000 |

1100 |

1/2" |

.75-7.5 |

.01-.17 |

25-250 |

14500 |

1815 |

3/4" |

2-15 |

.05-.33 |

68-515 |

2950 |

740 |

7/8" |

3-30 |

.07-.71 |

100-1000 |

2350 |

1175 |

1" |

5-50 |

.11-1.19 |

170-1700 |

900 |

750 |

1.5" |

15-180 |

.35-4.3 |

515-6000 |

325 |

975 |

2" |

40-400 |

.9-9.3 |

1300-13000 |

55 |

365 |

3" |

60-600 |

1.4-14.3 |

2100-21000 |

57 |

570 |

4" |

100-1200 |

2.4-28.5 |

3400-41000 |

30 |

600 |

6" |

200-2500 |

4.7-60 |

6800-86000 |

7 |

290 |

8" |

350-3500 |

8.3-83 |

12000-120000 |

3 |

175 |

10" |

550-5500 |

13-130 |

19000-180000 |

1.6 |

147 |

Material

| Material |

| Flow Meter Body: |

316 S.S. OR A-286 ALLOY |

| Sleeve Bearings: |

Tungsten Carbide |

| Shaft: |

Tungsten Carbide |

| Rotor: |

CD4MCu |

| Support Vanes: |

316 S.S. |

| Thrust Ball: |

Ceramic |

Performance

| Performance |

| Repeatability: |

Within +/-0.1% of indicated flow throughout the linear flow range |

| Linearity: |

Within +/-1% of the K-Factor throughout the linear flow range (Note: 3/8" +/-2%) |

|