|

热线电话: 010-8428 2935 |

||

|

Trelleborg特瑞堡行业应用Accelerating performance in your industry 我们致力于提供工业化解决办法,并且为用户提供定制化的密封和轴承解决方案,提高其应用性能。尤其在下列行业内我们拥有丰富的经验和成熟的系统解决方案。 Since we specialize in industry-specific solutions, we are able to provide customers tailor-made sealing and bearing solutions, specifically developed to meet their application requirements. In particular, we have long term experience in sealing and bearing applications within the following sectors: Trelleborg 特瑞堡密封系统是全球领先的密封解决方案供应商。 我们的产品范围包括 O形圈 , 液压密封件 , 旋转密封件 , 油封 , 静态密封件 , 气动密封件 , 机械端面密封件等等。 Trelleborg Sealing Solutions is a leading global supplier of sealing solutions. Our range of products includes O-Rings , hydraulic seals , rotary shaft seals , oil seals , static seals , pneumatic seals , mechanical face seals and many more. Trelleborg特瑞堡密封系统半导体密封件Semiconductor Seals 我们致力于提供工业化解决办法,并且为用户提供定制化的密封和轴承解决方案,提高其应用性能。尤其在下列行业内我们拥有丰富的经验和成熟的系统解决方案。 Since we specialize in industry-specific solutions, we are able to provide customers tailor-made sealing and bearing solutions, specifically developed to meet their application requirements. In particular, we have long term experience in sealing and bearing applications within the following sectors: 应对密封行业解决方案的挑战我们与半导体行业客户紧密合作,寻求能好地发挥客户设备性能的密封材料和密封设计。

半导体解决方案一站式服务

半导体密封产品系列包括:

探索特瑞堡适用于不同半导体环境的密封解决方案:严苛的化学环境

在半导体制造中,密封件经受熟知的一些苛刻的化学介质,包括:具破坏性的酸,碱,溶剂和气体。 大化密封兼容性 特瑞堡密封系统致力于大限度地提高标准密封配方与介质的兼容性,以及开发特殊化合物,如全氟弹性体材料IsolastFabRange。 IsolastFabRange密封材料几乎普遍兼容所有介质和气体,先进的TurconPTFE基化合物也是如此。 易于选择佳的半导体密封材料 为了确定适合您应用的佳半导体密封材料,请使用在线工具, 化学兼容性 。 高温

大化密封性能 密封件必须能承受高于300°C / 572°F的温度,主要要求是低释气和小颗粒产生。 特瑞堡密封系统的密封材料经证明可在连续升高的温度下成功运行,同时可承受高要求的化学品和介质。 推荐的半导体密封材料和产品:

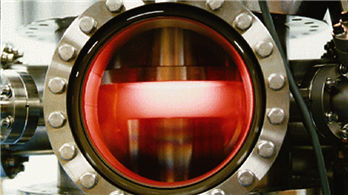

等离子系统

在半导体晶片制造期间的各个阶段均会使用到等离子体。 当气体经受能量,破坏其分子完整性并将其离解成离子和电子时,会产生等离子体状态。 在半导体工艺中用于此操作的许多气体是有毒的,反应性的和自燃的。

推荐半导体密封材料:

真空技术

真空技术 在半导体制造中起着关键作用,是工艺产量和生产率的关键。半导体应用范围从干泵到更复杂的子系统,用于光刻等工艺。保持一致的真空是至关重要的,因为即使是微小的波动也会对整个生产周期产生负面影响。 通过严格的测试的密封解决方案 TurconVariseal在半导体应用中进行了测试。对密封件进行氦气喷涂,并用密封氦气至10-6毫巴/秒,密封空气至10-9毫巴/秒。这些是聚合物密封件的杰出水平。 半导体真空应用密封件:

湿法工艺

半导体湿法工艺步骤包括蚀刻,剥离,电镀和CMP(化学机械抛光技术,然后进行晶圆清洗,除去所有表面污染物:颗粒,有机物,金属和天然氧化物的。 此外,所有使用的液体必须具有极高的纯度。 这些化学密集型半导体工艺涉及湿法化学品,包括酸(如氢氟酸),碱性溶液(如氢氧化钠和溶剂,通常是N-甲基吡咯烷酮或丙酮)。 密封件具有通用耐化学性 佳密封性对于确保整个ULSI(超大规模集成)过程的大化正常运行时间至关重要。 特瑞堡密封系统提供的半导体密封材料具有通用的耐化学性,能大程度地析出离子杂质,并且在湿法工艺应用中具有极低的颗粒化。

创新工程密封选择 基于多年密封方案设计经验,特瑞堡密封系统可以从广泛的创新密封产品中推荐佳密封方案,其中许多产品专为满足半导体行业日益严苛的工况而设计。 充气密封

Airseals是由管状弹性体制成的可充气密封件,通过内部加压激活。 它们非常适用,例如洁净室中的真空锁和通道门,从而取代了传统的平垫圈和O形圈,在这些专业应用中提高了性能。 金属组合密封

特瑞堡密封系统可以有效地将 FKM 和 Isolast 和不同材料,如不锈钢和低碳钢,铝,黄铜和各种塑料等制作成组合密封件。 经济有效地大化密封完整性 组合金属密封件的优点是:

Fleximold

凭借专有的FlexiMold技术,特瑞堡密封系统可以 生产高精度,大直径的O形圈和其他密封型材 。 FlexiMold巨型密封件的 质量远优于 那些通过拼接密封件或由挤压线圈制成的密封件。 大限度地缩短了交货时间和降低工具成本 各种弹性体制成的大型密封件

大型O形圈和密封件主要用于半导体工业中的 平板显示器 生产。 O形圈

特瑞堡密封系统提供各种O形圈,可在成本效益和性能之间取得平衡。 可提供任何尺寸的O形圈(标准或定制),包括使用Fleximold工艺的巨型O形圈。 广泛的密封材料选择 从基本弹性体到专为行业开发的领先化合物。 推荐材料

点击查找更多有关于 O形圈 和Fleximold的信息 Turcon Varilip PDR

TurconVarilipPDR (高性能,耐久,可靠) 旋转轴密封 件由一个或 多个TurconPTFE基材密封元件 构成,固定在 精密加工的金属体中 。

该密封件具有低摩擦和无爬行的特点,可 降低温度 , 允许更高的圆周速度并降低功耗 。测试表明, 在Fomblin油 (通常用于半导体真空泵)中运行时,TurconVarilipPDR的扭矩( 仅相当于径向油封扭矩的50%左右 )。这样可以延长服务寿命,维修将时间大限度地延长,从而提高生产率。

低摩擦, 有助于减少功率磨损和摩擦生热 金属体 耐用 于恶劣环境 Overall Turcon Varilip PDR seal 有助于降低设备的功耗 Turcon Variseal现场证明,在极端的气体和液体处理情况下,Variseal弹簧通电Turcon-PTFE基密封件已用于苛刻的半导体密封应用,包括高真空和腐蚀性环境Field-proven in extreme gas and liquid handling situations, Variseal spring-energized Turcon PTFE based seals have been used in the most demanding of semiconductor sealing applications , including high vacuum and corrosive environments. 系统完整性高High level of system integrity 通过正确选择聚四氟乙烯,填充聚四氟乙烯化合物和适当的弹簧材料和型材,Turcon Variseal可以提供高水平的系统完整性。With the correct selection of PTFE, filled PTFE compounds and appropriate spring material and profile, Turcon Variseal can provide the highest level of system integrity . 对于静态和动态应用,Turcon Variseal具有低摩擦特性,从而延长了使用寿命。For static and dynamic applications, Turcon Variseal demonstrates low-friction characteristics, leading to extended service life . Turcon Variseal NW

The Turcon case of this flange seal encompasses the energizing spring in such a way that there can be no possible contact between the spring or spring cavity and system media . Ideal for semiconductor applications, it can operate in a vacuum and is proven in fluorine gas. Features of the Turcon Variseal NW seal:

Turcon Variseal PS

这种高性能密封件采用Turcon-PTFE基密封体设计,包括一个聚合物弹簧弹簧设计用于在低压下精确地为密封件通电,同时使用系统介质压力保持高压密封的完整性。Turcon Variseal PS具有符合半标准F57-0301的超低滤出杂质和小的排气量,非常适合用于半导体湿法加工。This high-performance seal has been designed with a Turcon PTFE based sealing body, encompassing a polymeric spring. The spring is engineered to energize the seal precisely at low pressures, while maintaining high-pressure sealing integrity using the system media pressure. The Turcon Variseal PS has ultra-low leach out impurities as per SEMI standard F57-0301 and minimal outgassing , making it ideal for use in semiconductor wet processing. Features of the Turcon Variseal PS seal: Turcon Variseal PS密封的特点:

Turcon Variseal Ultra Clean

这一涡轮极其干净的密封在清洁的终极,使它理想地在处理设备中使用,在那里保持一个极其干净的系统是一个优先事项。在独特的超清洁涡轮设计中,激活海豹的春季要求完全封闭在涡轮内。在半导体制造中,当定时污染可以抑制波纹效应时,可提取的金属被完全排除在外。This Turcon Variseal Ultra-Clean seal offers the ultimate in cleanliness , making it ideal for use in processing equipment where maintaining an ultra-clean system is a priority. In the unique design of Turcon Variseal Ultra-Clean, the spring required to activate the seal is fully enclosed within a Turcon case. This means, in semiconductor fabrication, where the minutest contamination can destroy the effectiveness of wafers, metal extractables are totally excluded. Features of the Turcon Variseal Ultra-Clean seal: 涡轮变压器超清洁密封的特征

V-Ring

V形密封圈是一种独特的旋转轴全橡胶密封件,在保留润滑剂的同时,提供了防止介质(包括污垢、灰尘和水)进入的完美解决方案。典型的应用是化学机械抛光或晶圆切割设备,其工作速度可达12 m/s/39 ft/s。A unique all rubber seal for rotary shafts , V-Ring offers the perfect solution to prevent ingress of media including dirt, dust and water while retaining lubricant . Typical applications are on chemical mechanical polish or wafer dicing equipment, where it operates at a velocity up to 12 m/s / 39 ft/s. Recommended sealing materials:

Wills Rings

Wills Rings是初的金属密封件,设计用于超过聚合物密封能力的极端条件下使用。Wills Rings are the original metal seals engineered for use in extreme conditions where the capabilities of polymeric seals are exceeded. 在苛刻的条件下证明 在低温至850°C/1562°F的温度下工作,它们可承受高达1000兆帕/145038磅/平方英寸、10000巴的硬真空压力。它们是连接器、法兰和板静态密封的理想选择Proven in the most demanding of conditions 可用于各种型材和金属 Wills Rings可用于多种金属中,包括o形截面或c形截面,可充压或系统压力激活。Available in various sections and metals Click here to find our Wills Rings product pages:

材料Effective FKM Sealing

氟橡胶(FKM)密封件非常适合下游应用,如真空泵和温度不超过220°C/428°F的湿工艺应用。Fluoroelastomer (FKM) seals are ideal for downstream applications such as vacuum pumps and wet process applications where temperatures do not exceed 220°C/428°F. 我们的一系列fkm密封材料对半导体工业中使用的各种化学品表现出优异的耐腐蚀性,同时为半导体真空应用提供低渗透和放气水平的高纯度。Our range of FKM sealing materials exhibits excellent resistance to a wide range of chemicals used in the semiconductor industry, while offering high purity with low permeation and outgassing levels for semiconductor vacuum applications. Products:

Isolast Fab Range

Isolast Fab Range offers the ultimate in elastomer sealing. 这些高性能全氟弹性体(ffkm)实际上是惰性的,并且在高达325oC/617的连续温度下工作时显示出几乎普遍的化学相容性。These high-performance Perfluoroelastomers (FFKM) are virtually inert and demonstrate almost universal chemical compatibility while operating at continuous temperatures up to 325°C/617°F. Industry specific sealing Isolast J9610 for wet process applications - the highest level of chemical resistance. 用于湿工艺应用的Isolast J9610-高水平的耐化学性

isolast fab系列密封材料可用于标准和非标准o形环、工程模压密封设计或与金属密封部件粘合。密封件在洁净室环境中制造和包装。The Isolast Fab Range sealing materials are available in standard and non-standard O-Rings, engineered molded seal designs or as bonded to metal sealing components . Seals are manufactured and packaged in a cleanroom environment. Resifluor 500 increases flexibility

Resifluor 500系列由具有改性聚合物结构的优质fkm密封材料组成。树脂氟500化合物的设计结合了三元乙丙橡胶对极性流体、碱和酸的耐化学性,以及fkm密封材料在各种要求流体中的性能特点。The Resifluor 500 range consists of premium FKM sealing materials with modified polymer architecture. Resifluor 500 compounds are engineered to combine the chemical resistance of an EPDM towards polar fluids, alkalis and acids, with the performance characteristics of FKM sealing materials in a variety of demanding fluids. Seals with outstanding resistance阻力大的密封件 Resifulor 500密封范围具有优异的抗大量化学品和液体攻击能力。它具有低总有机碳和类似于聚四氟乙烯的金属可萃取性,提供了卓越的清洁度。The Resifluor 500 sealing range has outstanding resistance to attack by a large number of chemicals and fluids . It has low total organic carbon and metal extractables similar to PTFE, providing exceptional cleanliness . Products

Unique Turcon compounds

Turcon是Trelleborg密封解决方案系列专有聚四氟乙烯基密封材料的名称。Turcon is the name for the Trelleborg Sealing Solutions range of proprietary PTFE based sealing material. 从本质上讲,聚四氟乙烯(PTFE)与几乎所有的化学品都兼容,使其成为密封件可能暴露在苛刻介质中的设备的理想选择。通过添加填料和特殊加工技术,可获得特定的操作性能。Inherently, Polytetrafluoroethylene (PTFE) is compatible with almost all chemicals, making it ideal for use in equipment where seals are likely to be exposed to demanding media. Specific operating properties are achieved by the addition of fillers and special processing technologies. 动态和旋转密封元件Dynamic and rotating sealing elements Turcon sealing materials:

The world's largest manufacturer of PTFE based seals Trelleborg密封解决方案公司是世界上大的此类密封材料制造商,没有其他密封供应商能提供如此广泛的等级所有这些都是我们在欧洲、美国、南美和亚洲的工厂生产的。Trelleborg Sealing Solutions is the world's largest manufacturer of seals in this type of material, and no other sealing supplier can offer such a wide range of grades . All of these are produced at our own facilities in Europe, US, South America and Asia. Turcon密封材料是在各种不同的密封几何形状下制造的以下是半导体行业常用的密封类型:Turcon sealing materials are manufactured in a wide range of different seal geometries. Those listed below are the seal types most commonly used in the semiconductor industry: Products

Advanced engineered thermoplastics

高性能工程热塑性塑料为聚醚醚酮(PEEK)和聚酰亚胺等材料提供了新的密封解决方案它们能承受高工作温度,表现出良好的耐化学和等离子体性能,静电控制和低放气。High-performance engineered thermoplastics offer novel sealing solutions in materials such as PEEK (Polyether Ether Ketone) and polyimide . These withstand high service temperatures, demonstrate good chemical and plasma resistance, electrostatic control and low outgassing. From bearing to bellows 从轴承到波纹管 HiMod wear rings and bearings从轴承到波纹管和轴承 已在许多半导体应用中证明是成功的,这些应用要求卓越的尺寸稳定性和低颗粒脱落。have proved successful in a number of semiconductor applications which require outstanding dimensional stability and low particle shedding. 专业的Turcon PTFE组件包括波纹管。它们为橡胶接头提供了高纯度和化学相容的选择。Specialized Turcon PTFE based components include bellows. They offer a high-purity and chemically compatible option for rubber joints. 佳解决方案The optimum solution

Trelleborg Sealing Solutions works with semiconductor customers in development partnerships .我们可以共同确定一个适用于材料和海豹剖面的宽选择的佳封装选择。 Together we can identify the best sealing option for specific applications from a broad choice of materials and seal profiles. 探索我们的解决方案Explore our solutions 新的半导体工艺要求越来越多。为了满足这些需要,开发了创新的封装解决方案,如下面列举的那些解决方案。The latest semiconductor processes have increasingly challenging requirements . To fulfill these needs, innovative sealing solutions such as those listed below, are developed.

Longer life in CVD Equipment CVD设备使用寿命更长

密封问题Sealing issue: cvd设备的用户对密封产品的质量要求很高。高真空需要超干净的密封以防止污染。此外,通常有非常苛刻的化学和/或热环境。The users of CVD equipment require high-quality sealing products. High vacuums need ultra-clean seals to prevent contamination. In addition, there are often very demanding chemical and/or thermal environments. 我们的客户一直在寻求改进其产品,所以他们在现有的应用中尝试了隔离环J9670材料中的O形密封圈。Our customer is always looking to improve its products, so they tried out O-Ring seals in Isolast J9670 material within existing applications. 解决方案Solution: 由ISOLAST J9670制造的O型环。该专利全氟弹性体化合物是isolast fab range之一,专为半导体应用而设计。它的设计工作温度高达315°C/599°F,对几乎所有化学物质都具有优异的抵抗能力。O-Rings manufactured from Isolast J9670 . This proprietary perfluoroelastomer compound is one of the Isolast Fab Range especially engineered for semiconductor applications . It is designed to operate at temperatures up to 315°C / 599°F and offers superior resistance to almost every chemical. 结果Result: 在各种等离子体气体中测试了六个月后,密封件没有裂纹特别是,这种密封比以前的密封更能抵抗SF6等离子体气体。这意味着Isolast J9670的使用寿命更长。After six months of testing Isolast J9670 within various plasma gases, there were no cracks in the seals . In particular, the seals proved more resistant to SF6 plasma gas than previous seals. This meant that Isolast J9670 gave a longer operating life . 在过去的两年半中,客户在其设备中集成了Isolast J9670密封件。For the last two-and-a-half years, the customer has integrated Isolast J9670 seals in its equipment. 在等离子体中保持真空Maintaining a vacuum in plasma

密封问题Sealing issue: 任务是密封进入加工室的旋转进料需要保持500托的真空,同时密封以容纳反应性等离子体气体。试验室连续使用一小时,每小时关闭五分钟。The task was to seal a rotary feed-through that went into a process chamber. A vacuum of 500 Torr needed to be maintained along with a tight seal to contain reactive plasma gases . The chamber was in continuous use for one hour with a five minute shut-down each hour. 解决方案Solution: 带有Turcon T78护套和中等负荷哈氏合金弹簧的Turcon Variseal CM及其产品Turcon Variseal CM with a Turcon T78 jacket and medium-load Hastelloy spring along with an Products 结果Result: Turcon Variseal厘米能够在间歇工作期间保持所需的真空,同时暴露在等离子体气体中。The Turcon Variseal CM was able to hold the required vacuum during intermittant service while exposed to the plasma gases. 使用条件Service Conditions:

电动无级变速电机旋转密封Rotary seal for electric CVD motor

密封问题Sealing issue: 任务是用一种化学惰性、无污染、长寿命的密封件取代目前的橡胶唇形密封。这必须改装成现有的硬件。The task was to replace the current rubber lip seal with a chemically inert, non-contaminating, long-life seal. This had to be retrofitted into existing hardware. 解决方案Solution: Turcon T78中的Turcon Varilip PDR,以低放气FKM O型环作为激发剂。Turcon Varilip PDR in Turcon T78 with low outgassing FKM O-Ring as an energizer. 结果Result: Turcon T78材料在应用中对所需气体提供了有效的阻力,并延长了电机的使用寿命。The Turcon T78 material provided effective resistance to the demanding gases within the application and also extended the service life of the motor. 使用条件Service Conditions:

通过严格的泄漏测试Passing strict leakage tests

密封问题Sealing issue: 像氦这样的轻气体尤其难以密封,因为它们能够渗透到表面光洁度的山谷中。Light gases like helium can be especially difficult to seal because of their ability to permeate through even the valleys of a surface finish. 再加上高真空,这种应用非常困难,要求密封件通过严格的泄漏试验。此外,密封槽必须保留密封件,以便在密封件不脱落的情况下将其从石英上提起。Combined with high vacuum, this application was very difficult and required the seal to pass strict leakage tests. Also, the seal groove had to retain the seal so that it could be lifted from the quartz without the seal falling out. 解决方案Solution: 定制turcon variseal mf,带有turcon t01护套和两个嵌套的重载v形弹簧。Custom Turcon Variseal MF with a Turcon T01 jacket and two nested heavy-load V-springs. 结果Result: 如上图所示夹紧密封件不仅将其保留在槽内,而且消除了一条泄漏路径。嵌套的V形弹簧在密封套上提供了所需的载荷,以满足严格的泄漏要求Clamping the seal as shown in the diagram above not only retained it within the groove but eliminated one leakage path . The nested V-springs provided the required load on the seal jacket to pass the strict leakage requirements. 使用条件Service Conditions:

产品Products: 变压密封MF V形弹簧通电端面密封Variseal MF V-spring-energized face seal Isolast有助于减少维护Isolast helps reduce maintenance

密封问题Sealing issue: 作为工厂制造过程的一部分,在薄膜沉积的每一个处理步骤之后,一个干燥的“条状”系统从wafers上去除光刻胶和残留物。As a part of the fab manufacturing process, following each processing step of film deposition, a dry ‘strip' system removes photoresist and residues from wafers. 为此,wafers在高温下暴露在气态氧等离子体中。这导致系统内的密封件迅速恶化,频繁更换密封件中断生产。To do this the wafer is exposed to gaseous oxygen plasma at high temperatures. This was causing seals within systems to quickly deteriorate , interrupting production with frequent seal changeover. 解决方案Solution : O型环由ISOASTA FAB系列J9670制造,专门设计用于高温等离子体环境,取代了现有的密封件。O-Rings manufactured from Isolast Fab Range J9670, specifically engineered for high temperature plasma environments, replaced the existing seals . 结果:延长了维护周期,在更换密封件期间,硅片产量从15000-20000片增加到50000片以上。这满足了制造商的目标,即增加计划维修之间的平均时间,提高总产量和降低成本。Result: Maintenance cycles were extended, increasing production from 15,000-20,000 to over 50,000 wafers between seal changes. This met the fab manufacturer's aim of increasing mean time between planned maintenance, improving overall production yield and lowering costs. isolast降低了成本Isolast lowers cost of ownership

密封问题Sealing issue: 一家主要的wafer探针卡制造商在生产过程中使用了等离子蚀刻设备,密封件暴露在要求很高的等离子和清洗剂中。A major manufacturer of wafer probe cards used plasma etch equipment in their production process and seals were exposed to demanding plasmas and cleaning agents . 安装在等离子蚀刻设备上的O型环作为定期预防性维护定期更换客户希望通过延长计划维护之间的交货期来降低拥有成本。O-Rings fitted in plasma etch equipment were regularly replaced as a matter of scheduled preventative maintenance. The customer wanted to lower cost of ownership by extending leadtime between planned maintenance. 解决方案Solution: O型环由ISOASTA FAB系列J9670制造,专门设计用于高温等离子体环境,取代了现有的密封件。O-Rings manufactured from Isolast Fab Range J9670 , specifically engineered for high temperature plasma environments, replaced the existing seals. 结果Result: 由Isolast Fab Range J9670制造的O形密封圈证明延长了密封寿命这意味着可以延长计划维护之间的提前期,并达到降低拥有成本的目标。The O-Rings manufactured from Isolast Fab Range J9670 proved to give extended seal life. This meant leadtimes between planned maintenance could be lengthened and the objective of lowering cost of ownership was met. 消除泄漏Eliminating leakage

密封问题Sealing issue: 此应用中的密封件需要通过两次泄漏测试-氦泄漏不能超过10 cc/sec,当密封水时,密封件必须是自由下落的还需要低摩擦。The seal in this application was required to pass two leakage tests— helium leakage could not exceed 10 cc/sec , and when sealing water, the seal had to be drop-free . Low friction was also required. 解决方案Solution: 法兰连接Flanged

FW with a

T05夹套和中载斜螺旋弹簧。T05 jacket and medium-load Slantcoil spring . 结果Result: 在这种应用中,法兰式Turcon Variseal FW被用于有效地消除O.D.的泄漏,而介质弹簧提供了正确的负载,以实现摩擦和密封性之间的平衡。In this application the flanged Turcon Variseal FW was used to effectively eliminate leakage across the O.D. , while the medium spring provided the correct load to achieve a balance between friction and sealability. 使用条件Service Conditions:

产品Products: Turcon Variseal w斜线圈带电杆密封Turcon Variseal W Slantcoil-energized rod seal Turcon Variseal FW斜线圈通电法兰密封Turcon Variseal FW Slantcoil-energized flange seal

|

|